Presta Cylinders comprises a test laboratory for checking all LPG-related articles.

Comprehensive laboratory

We have created a laboratory that includes the latest technology for inspecting cylinders, valves and any other product related to our activity

We aim to:

- Provide quality control for components at process input

- Provide quality control for end products

- Develop new tests for products

- Develop new products

We also offer our material and expertise on laboratory testing and analyses to our own customers and to any other business that may require such testing. Our sales department is on-hand to provide you with more information on the testing and expertise we can offer you.

Description of Presta Cylinders’ specific capabilities

Caisson for rupture testing

For testing cylinders and valves under increasing pressure (up to 100 bars), under completely safe conditions for operators

Salt spray cabin

For prolonged resistance/stress testing under highly-corrosive conditions

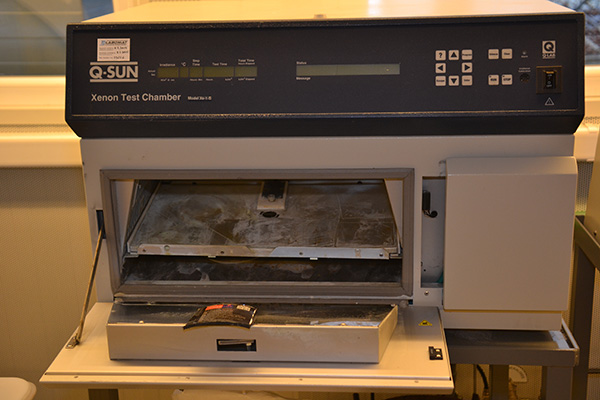

Xenon chamber

For accelerated resistance/stress testing to extreme light exposure. Used to qualify paint, pigments and various synthetic materials.

Spectrophotometer

For making quantified characterizations of colours in relation to a standard.

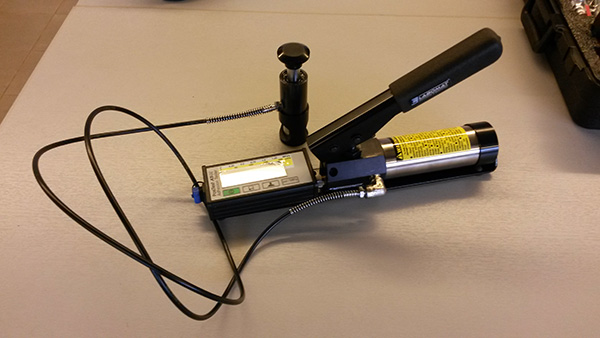

Pull-off test

For assessing grip between different surfaces (paint, self-adhesives, etc.).